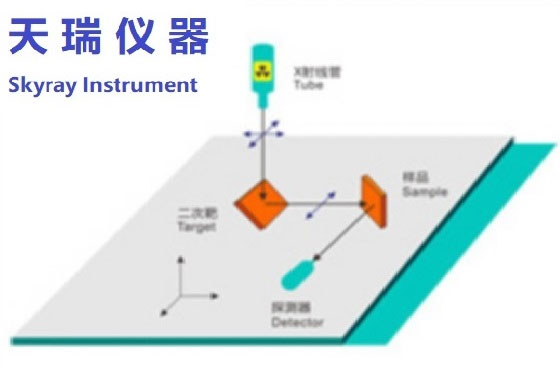

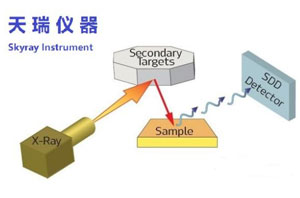

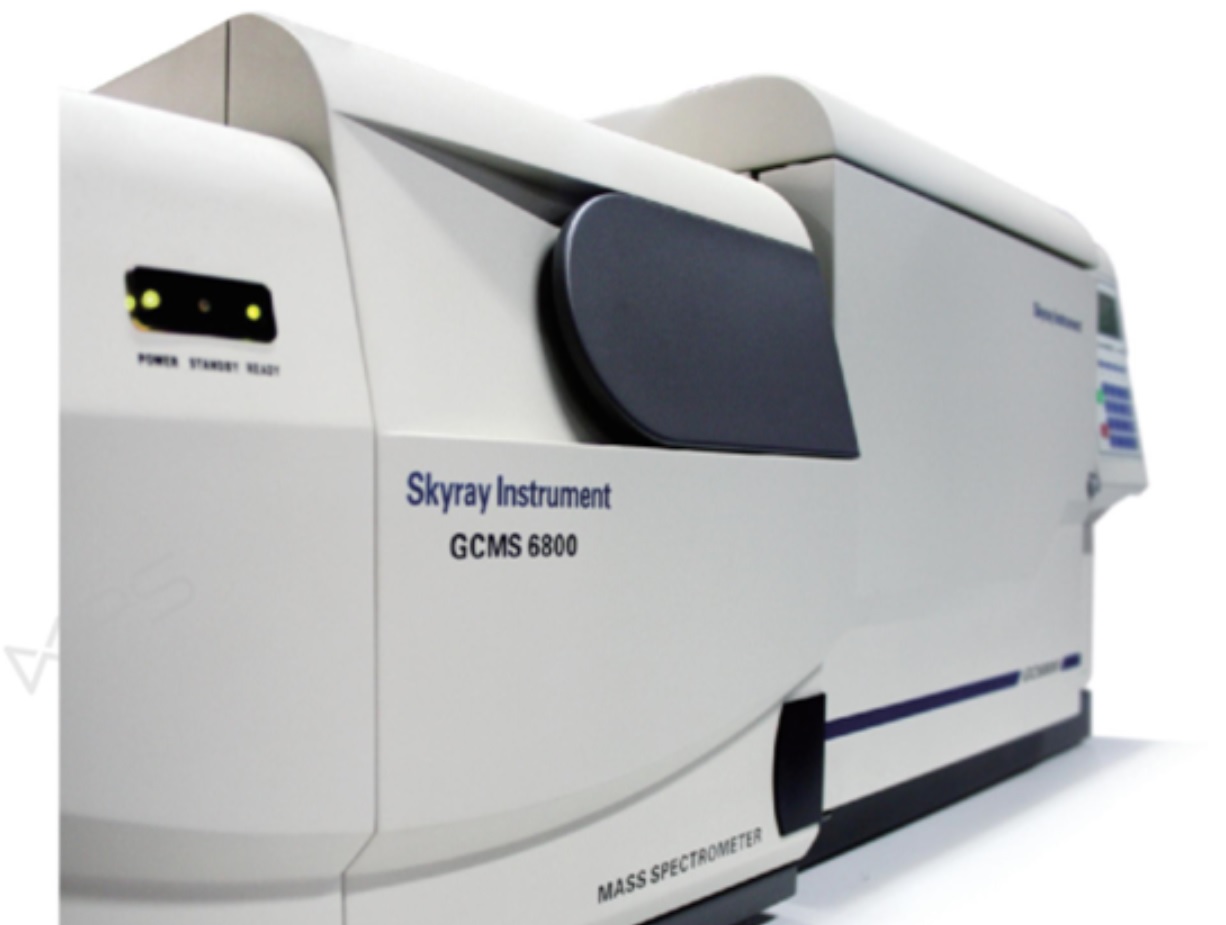

Atmospheric Heavy Metal On-line Analyzer uses Skyray Instrument's patented technology—X-ray fluorescence (XRF) non-destructive testing technology and atmospheric auto-enrichment technology. It is in line with US EPA IO-3.3 standard method; the system uses a unique X-ray excitation light source and sample. Exciting structures, detection systems, automatic enrichment, automatic roll-winding systems and other core technologies greatly increase the detection sensitivity of heavy metals in airborne particulates, enabling the detection of heavy metals such as lead, cadmium, chromium, and arsenic at low levels, while enabling unattended operation. (1~3 months) automatic monitoring for a long time.

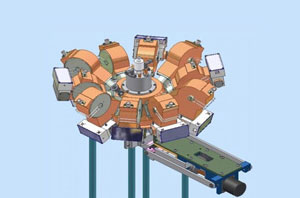

Instrument host

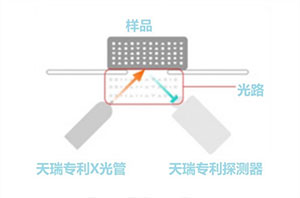

Including particle enrichment system (cutter, DHS dynamic heating device, flow measurement control device, sampling pump), coil membrane system (PTFE membrane volume <with a very low background element content>, membrane movement device), X fluorescence analysis system (High-power X-ray tube, SDD X fluorescence detector, multi-filter switching device, digital multi-channel analyzer, FP algorithm analysis software), control system (control sampling, film movement, XRF detection, flow recording and control, Calculation of pollutant concentration, results display, etc.). In addition to the particulate cutter and the sampling pump, these four systems are all integrated in a single chassis for easy transportation and installation.

Heavy metal workstation

Hardware Configuration:

(1) Integrated integrated touch screen IPC can store more than 10 years of data. (Can also be an external industrial computer, customized according to customer requirements)

(2) Interface configuration: Input and output interfaces 24V DC, 2A, RS232 serial port (Modbus protocol, maximum 38.4 kbps); the connection port of heavy metal workstations and instrumentation equipment is a network port to ensure bulk data transmission.

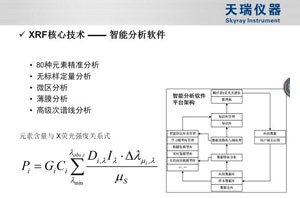

Software configuration:

(1) EHM-X100 control and comprehensive analysis software, Chinese operation interface, touch screen operation, display real-time sampling flow, sampling time, measurement status, heavy metal concentration value, content curve and other information; and self-diagnosis and setting function, real-time status Monitoring functions, and can store more than 10 years of monitoring data; software using advanced hierarchical modular design, with powerful and flexible data settings, calibration, preservation, display, query, analysis, transmission and other functions.

(2) The data complies with the "Data Transmission Standard for Pollution Source Online Automatic Monitoring (Monitoring) System" (HJ/T 212-2005). The open communication protocol can access the data mining platform and can guarantee the interconnection with provincial stations and national stations.

(3) The storage file providing monitoring data can be output in TXT text or EXCEL table; the software can save the spectrum scan spectrum of each measurement or calibration, and can search queries.

Particle cutter

The TSP, PM10, and PM2.5 cutters can be selected for measurement of heavy metal content in particles of different dynamic diameters. The cutter is certified by the authority. At the same time, it is equipped with an outdoor temperature sensor, shutter protection and lightning protection isolator.

With a special waterproof fixing flange for the roof, the cutter can be fixed on the roof. The user can also choose the vehicle platform to fix the cutter on the roof.

DHS dynamic heating system

When measuring PM2.5 particles, the effect of moisture in the air on the test can be eliminated.

Sampling pump and fan

It adopts high efficiency imported diaphragm pump, with a maximum flow rate of 168 L/min and a minimum vacuum of 60 Torr.

Through the high-pressure fan, the air is introduced into the host through the corrugated tube to dissipate heat for the X-ray tube, and the light tube is used to stabilize and prolong the service life.

Consumables

Filter membrane: Take an hourly sampling test as an example, a roll of membrane can be used for one month.

Fan air filter.

Working conditions

Measuring ambient temperature: -40°C~50°C

Measuring environment humidity: 0%RH~90%RH

Host operating environment temperature: 5 °C ~ 40 °C

Host working environment Humidity: 30% RH to 60% RH

Power supply: 220V AC±10%, 50Hz ± 1Hz

Performance characteristics

Advanced X-ray fluorescence (XRF) non-destructive testing technology combined with automatic atmospheric particle enrichment technology, in line with US EPA IO-3.3 standard method

Equipped with a variety of particle cutters for users to choose, realize the measurement of distribution of heavy metal particles on different dynamic diameters

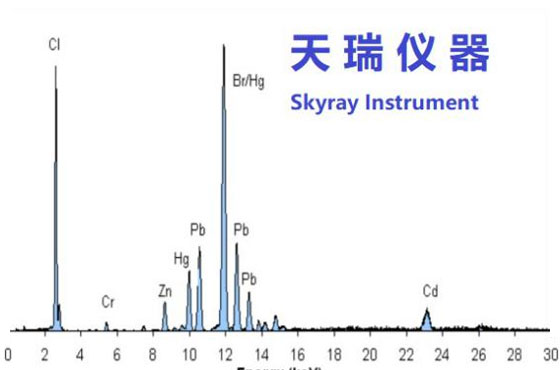

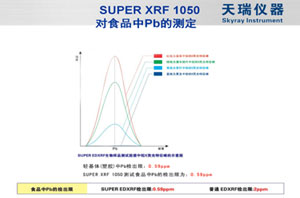

Accurate measurement of 30 kinds of heavy metals such as lead, cadmium, chromium, arsenic, etc. The best detection sensitivity is 10pg/m3, and the heavy metal elements can be expanded.

The host adopts the international standard 19” chassis, which can be installed on the mobile monitoring vehicle or on the standard cabinet of the atmospheric automatic station.

20 years of XRF technology accumulation, lightning protection industrial-grade electrical and electronic design, the instrument has a high degree of operational reliability and stability, 24-hour/365-day trouble-free operation, while also has intelligent fault diagnosis and self-exclusion function.

Miscellaneous peak light path design, built-in 3-speed filter, automatic switching to achieve low background measurement

Built-in calibration module, XRF spectrum vertical and vertical coordinates at the same time automatically calibrated, calibration frequency can be set arbitrarily, also built a specific metal internal standard source, can achieve automatic quality control and alarm

Through the mass flow controller and the temperature and pressure sensors, the sample flow rate can be precisely controlled and the flow rate can be automatically calibrated.

With RS232/485, USB, GPRS, ADSL, Ethernet and other data transmission methods, it can realize the remote transmission, monitoring and inspection of operating parameters, status and data.

The system software adopts advanced layered modular design, with powerful and flexible data settings, calibration, preservation, display, query, analysis, transmission and other functions. The data complies with the "Data Transmission Standard for Pollution Source Online Automatic Monitoring (Monitoring) System" (HJ/T 212-2005). At the same time, users can customize and expand any other custom functions quickly and easily.

Professional multi-radioactive treatment, measuring instrument without any radiation leakage in all directions

Application area

It can continuously measure and analyze various heavy metal particles in the atmosphere, and has the following applications:

Atmospheric quality monitoring

Environmental evaluation, permit

Air Particle Characteristics Analysis

Source location and source tracing

Atmospheric background measurement

Pollution forecast warning

Technical indicators

The main monitoring element: Pb (lead), which can simultaneously monitor Cd (cadmium), Hg (mercury), As (arsenic), Cr (chromium), Cu (copper), Zn (zinc), Ni (nickel), Ba (doping) ), Fe (iron), Ag (silver), Se (selenium), Br (bromine), Te (tantalum), Sb (tantalum), Sn (tin), Ti (titanium), Co (cobalt), Mn (manganese) Pd, Pd, Tl, Sc, Mo, Mo, V, Vanadium, Cs, Ga, Ca, K, Sr , Cl (chlorine) 30 kinds of elements (monitoring elements can be configured according to user needs); optional EPA I0-3.3 recommended corresponding element calibration diaphragm, can be traced according to NIST standards

Applicable standard: US EPA IO-3.3 standard method "X-ray fluorescence spectrometry detection of heavy metals in environmental particles"

Measuring range: 0 to 100 μg/m3

Minimum detection limit: 10 pg/m3 (sample analysis time 4 hours, flow rate 16.7 L/min)

Sample flow: 0 ~ 20L/min adjustable

Sampling analysis time: sampling period 15 to 1440 minutes, can be customized; requires continuous sampling, sampling and analysis process can be carried out at the same time, no sampling interval dead time

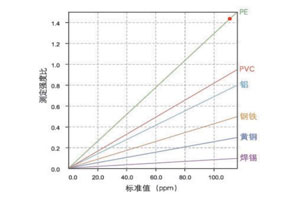

Linear correlation coefficient: > 0.99

Reproducibility: RSD < 0.5% (standard sample of Pb)

Accuracy: < 15% (Pb, compared with national standard laboratory methods, sampling time is greater than 1 hour)

Safety protection: Multiplex X-ray radiation safety protection device, radiation dose less than 2.5μGy/h (5cm from the chassis); the instrument door is opened to automatically close the X-ray tube to protect personnel safety

Working methods: continuous automatic monitoring; one year of trouble-free operation, and self-recovery function

Control mode: Computer control, self-diagnosis and setting function, real-time status monitoring, and can store more than 10 years of monitoring data

Operation interface: Chinese or English operation interface, touch screen operation, display real-time sampling flow, sampling time, measurement status, heavy metal concentration value (standard or non-standard state can be selected), content curve, etc.

Installation method: Fixed station house standard cabinet installation or mobile vehicle installation

Host size: 482mm (19”) x 420mm x 600mm (14U)

Chinese

Chinese Investor Relations

Investor Relations E-mail

E-mail Notice:

Notice: